A rotary distributor disperses the wet feed evenly over the back mix section equipped with contact heating surfaces immersed in the fluidized layer the heating surfaces provide a significant portion of the required energy and therefore it is possible to reduce both the temperature.

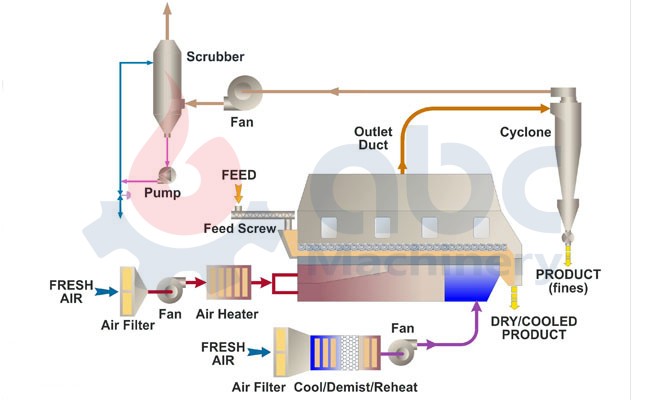

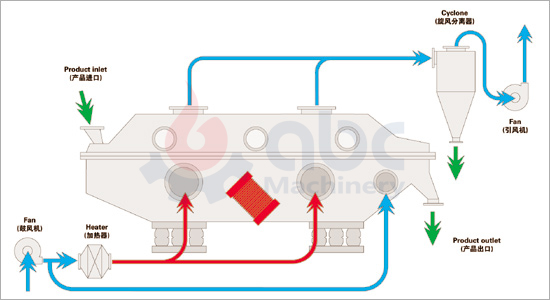

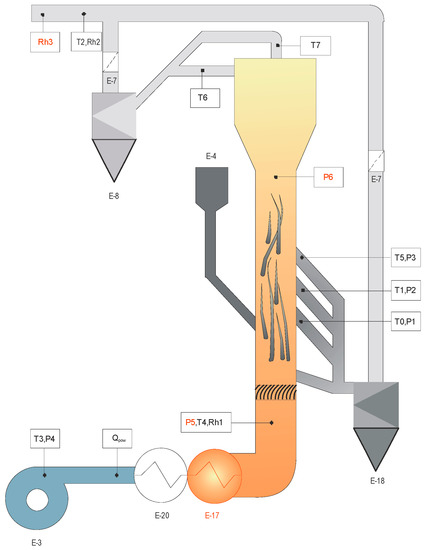

Horizontal fluidized bed dryer diagram.

Principle of the fluidized bed dryer a vibratory conveyor is leading the tobacco in an even layer through two drying zones.

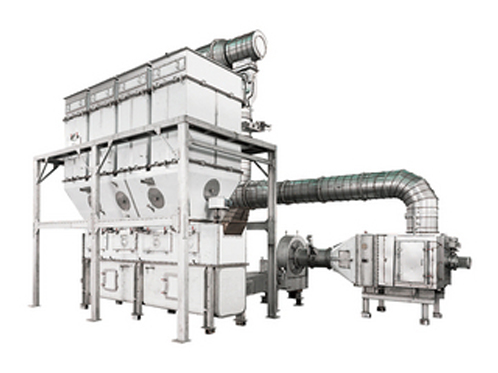

Fluidised bed dryer 1.

Senieer also has a 500kg fluid bed dryer even bigger we can custom design for you.

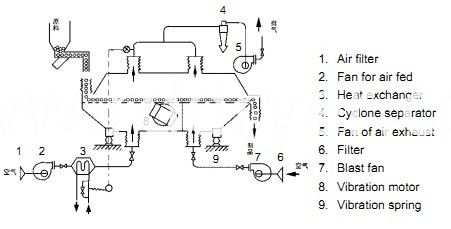

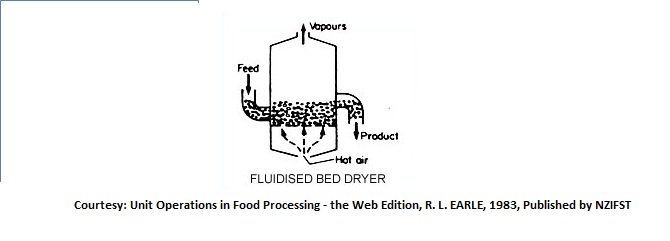

The equipment works on a principle of fluidization of the feed materials.

In heinen köhl standard process air will be conditioned in energy units following the closed loop principle.

Fluidized bed dryer 300 fluid bed dryer product container 300l production capacity 45kg to 135kg fluidized bed dryer laboratory fluid bed dryer capacity of 10l our lab fluid bed dryer with programmable parameters touch screen control etc.

Fluidized bed dryer also called fluid bed dryer is a kind of equipment used extensively in the pharmaceutical industries to reduce the moisture content of pharmaceutical powder and granules.

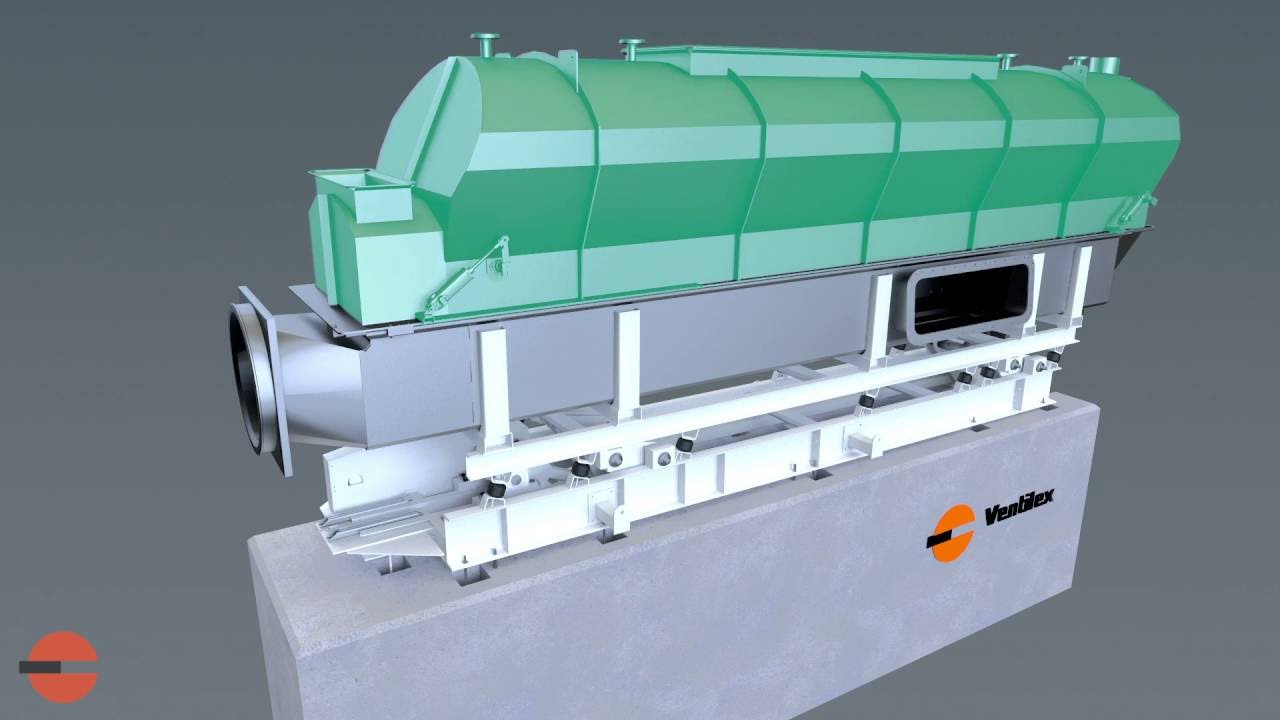

This is a rectangular fluid bed dryer incorporating back mix and mix flow sections.

The process air is supplied to the bed through a perforated distributor plate and flows through the bed of solids at a sufficient velocity to support the weight of particles in a fluidized state.

Fluidized bed dryers coolers.

The process air coming from the perforated bottom of the trough creates a homogeneous fluidized carpet.

This results in the medium then having many properties and.

A fluidized bed is a physical phenomenon occurring when a quantity of a solid particulate substance usually present in a holding vessel is placed under appropriate conditions to cause a solid fluid mixture to behave as a fluid this is usually achieved by the introduction of pressurized fluid through the particulate medium.

The principle of operation of fluidized systems are based on the fact that if a gas is allowed to flow through a bed of particulate solids at velocity greater than the settling velocity of the particles and less than the terminal velocity for pneumatic conveying and equal to the minimum velocity.

Fluidized bed systems 2.

Materials processed in a fluidized bed dryer or cooler float on a cushion of air or gas.